Welcome to the website of Baotou lichen tech.Ltd. Hot search:Cerium based polishing powder, cerium based polishing slurry, rare earth polishing material

- Warm congratulations on the establishment of Lichen technology website!

- Congratulations to Baotou lichen tech.Ltd. on its website!

- Introduction to preparation of ceria polishing powder.

- What are the product polishing slurry?

- What material is used for polishing automobile glass? Is ceria polishing powder OK?

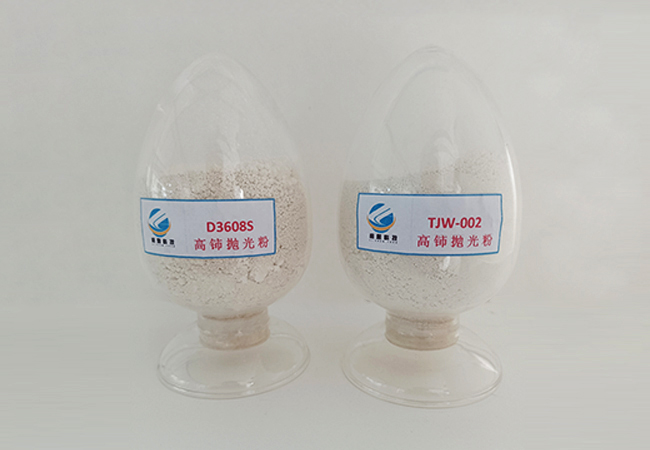

- Cerium based polishing powder

- Cerium based polishing slurry

- Cerium based polishing material

- Rare earth polishing material,cerium oxide polishing powder

- Cerium oxide polishing slurry

- Rare earth polishing slurry,rare earth polishing powder

- Cerium oxide rare earth polishing powder

- Cerium oxide rare earth polishing slurry

- Baotou lichen tech.Ltd.

- Tel:13848523690

- Email:kjlichen@163.com

- Address:South of MaoYuan East Road and east of Shuguang Road,rare earth application Park,rare earth high tech Zone,Baotou,Inner Mongolia

Preparation of cerium oxide polishing powder by gas phase method and spray pyrolysis method

source:www.btslckj.cn | Release time:2022年04月02日Ceria rare earth polishing powder was prepared by gas phase method.

Gas phase method refers to the method that two or more simple substances or compounds react in the gas phase to form new nano compounds. Gas phase method includes low-pressure gas evaporation, gas condensation, active hydrogen molten metal reaction, sputtering, electric heating evaporation, mixing of volatile compounds, laser-induced chemical vapor deposition, etc.

Cerium oxide polishing powder was prepared by spray pyrolysis.

Ultrafine powders of rare earth cerium oxide have been prepared by spray pyrolysis. Because they have many advantages such as liquid phase and gas phase, they have become a new method to prepare rare earth ceria ultrafine powder in recent years.

Spray pyrolysis is a continuous process. The particle shape is uniform and controllable. It does not require filtration, cleaning, drying, crushing and calcination in various liquid phases. In the above process, the operation is simplified, the industrial production is promoted, the introduction of impurities and the destruction of crystal structure are avoided, so as to ensure the high purity and high activity of the product. At present, this method has been used to prepare some rare earth ceria nanoparticles, but it has not been reported in the preparation of nano dioxide. Therefore, conditional readers can try.

*Disclaimer: the reprinted contents are from the Internet. If you have any objection, please contact in time and I will delete them.

【Related articles】

【Related products】

+

WeChat ID:13848523690

WeChat ID:13848523690

WeChat ID:13848523690

WeChat ID:13848523690

Home

Home

Add WeChat

Add WeChat

Contact us

Contact us

Telephone

Telephone